Why FRP Composites Are Revolutionizing Industrial Flooring

Industrial flooring must withstand heavy loads, harsh chemicals, and constant foot and machinery traffic. Traditional materials like concrete or metal often fall short, facing corrosion, wear, and costly maintenance. Fiber-Reinforced Polymer (FRP) composites are changing the game, offering a modern, durable, and cost-effective alternative.

1. Exceptional Corrosion Resistance

FRP composites are highly resistant to chemicals, moisture, and environmental exposure. Unlike metal floors that rust or degrade, FRP flooring maintains its integrity in chemical plants, wastewater facilities, and coastal structures.

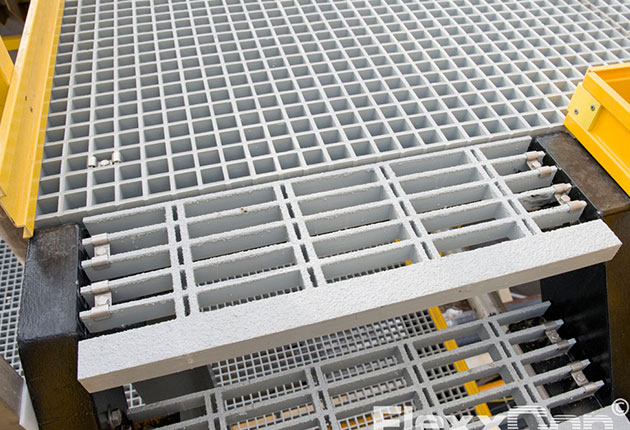

2. Lightweight and Strong

Despite being lightweight, FRP composites provide excellent structural strength. This makes installation easier, reduces the load on supporting structures, and ensures long-term durability.

3. Low Maintenance and Long-Lasting

FRP floors require minimal upkeep. They resist cracking, warping, and chemical damage, drastically reducing maintenance costs over their lifespan compared to traditional materials.

4. Safety and Non-Conductivity

Many FRP flooring options are non-conductive and slip-resistant, improving safety in industrial environments with electrical equipment or wet surfaces.

5. Design Flexibility

FRP composites can be customized in thickness, size, color, and texture, making them suitable for walkways, platforms, mezzanines, and complex industrial layouts.

Conclusion

FRP composites are revolutionizing industrial flooring by combining durability, safety, and low maintenance with versatile design options. Industries across chemicals, wastewater, manufacturing, and infrastructure increasingly rely on FRP to deliver safe, cost-effective, and long-lasting flooring solutions.